Call us for questions!

Call us for questions!

Residential & Commercial

Polyaspartic flooring emerges as a superior choice when compared to traditional epoxy alternatives, offering a multitude of advantages that redefine the standards of durability, aesthetics, and practicality. Heres why Polyaspartic stands out as the premium flooring solution:

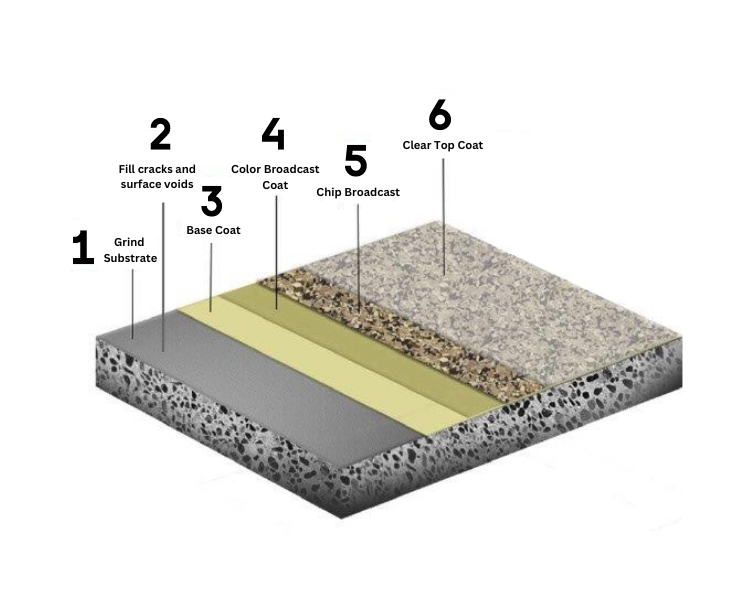

Polyaspartic is high performance and is a durable coatings system. It has revolutionized the concrete coating industries since 1980. The application is a multi-layered system by rolling & squeeging. A polyaspartic coating is a protective layer of aliphatic polyurea that is applied to concrete floor surfaces.

THE PREMIUM SMART FLOOR SYSTEM

GRINDING FLOORS

Required to prep the concrete surface to rid of any resins, curing agents, and contaminants. Surface prep for floors are ground between 80-100 grit.

Cracks & Joints:

When grinding these out, use a Crack Chaser to get the most surface area for crack fix materials to adhere to. After this is complete, grind the repair flush to the concrete floor.

1ST COAT: CLEAR BASE COAT

Installers lay down a polyaspartic clear base coat and occasionally add color pigment to help enhance color. that acts as a primer for the flooring.

The base coat penetrates the concrete to create a mechanical bond.

2ND COAT: COLOR COAT & CHIP

After applying a heavy color coat, fully saturate the floor with the vinyl chip.

This takes between 30-40 min. to dry.

SCRAPE & SAND

Once the color coat and chip layer is dried, scrape and sand to ensure an even and smooth surface.

TOP CLEAR SEAL COAT WITH SQUEEGEE

This layer seals in the color coat and chip.

We squeegee on the top coat and back roll in 2 directions for a complete finish.

FINAL RESULTS

Allow 24 hours for product to cure. It is recommended to wait 36 hours before putting heavy objects like cars or machinery on top of product.

THE PREMIUM SMART FLOOR SYSTEM

Rapid Cure Time:

Polyaspartic coatings boast an exceptionally fast curing process, often as quick as a few hours. In

contrast, epoxy coatings may take significantly longer to cure. This rapid cure time minimizes downtime,

allowing spaces to be functional in a shorter period.

Enhanced Durability:

Polyaspartic floors exhibit remarkable resistance to abrasions, chemicals, and UV rays, surpassing the

durability of traditional epoxy coatings. This resilience ensures a long-lasting and robust flooring solution even in high-traffic areas or harsh environmental conditions.

UV Stability:

Unlike epoxy, Polyaspartic is highly resistant to yellowing or degrading due to exposure to UV rays. This makes it an ideal choice for areas with abundant natural light, maintaining the aesthetic appeal of the

flooring over time.

Flexibility in Application Temperature:

Polyaspartic coatings can be applied in a broader range of temperatures compared to epoxy. This

flexibility allows for year-round installation, even in challenging weather conditions, providing

convenience and adaptability to various climates.

VOC Compliance:

Polyaspartic coatings typically have lower Volatile Organic Compound (VOC) emissions. This makes them a more environmentally friendly choice, contributing to better indoor air quality and meeting stringent environmental regulations.

Seamless Finish:

Polyaspartic coatings can create a seamless and smooth finish, eliminating joints or seams in the

flooring. This not only enhances the aesthetic appeal but also prevents the accumulation of dirt and bacteria in the seams, making it a hygienic choice for spaces with strict cleanliness requirements.

High-Quality Aesthetics:

Polyaspartic coatings offer a clear, glossy finish that enhances the overall visual appeal of the flooring. The clarity and brightness are maintained over time, providing a polished and professional look that outshines epoxy alternatives.

Reduced Maintenance Requirements:

Thanks to its robust nature, Polyaspartic flooring requires minimal maintenance. It resists stains,

chemical spills, and wear, ensuring a consistently attractive appearance with less effort and cost for

upkeep compared to epoxy.

CONTACT US